To say I have found it irksome to discontinue my daily psychoontyres blogs for the last couple of years would be an inderstatement. It has not been for want of encouragement or indeed enthusiasm, I nearly got it going again during lockdown but there were a million other things to sort out while everything went quiet and before I knew it I was off furlough and back at work. I am afraid future posts will be sporadic, if I can get one done every month I’ll count that as a success for now.

So excuses over I have author Mike Allen to thank for an e-mail he sent 18 months ago which has been needling my conscience to extract the proverbial digit and find my log in details to get the show back on the road. Mikes Dad James Neil Allen, known as Neil, bought a Ford Popular in 1955 and here in his own words is a description of the modifications he made to it.

The Ford Pop was produced from 1953. It was based on the pre-war Anglia but was stripped of every refinement originally on the Anglia, the most important from my point of view was the opening windscreen (In those days it could get VERY foggy). However the original capacity was increased from 933cc to the Prefects 1172cc giving 30bhp, Max speed 60mph. It only weighed 16cwt so didn’t feel underpowered. I bought mine on Sep 2nd 1955 for £395 from Frank Guest of West Bromwich.I drove away with a Ford 8 cylinder head (£2) in the boot. This had a ground surface but the cylinder heads were “as cast” and I spent many evenings recovering the sandy surface.

The Pop had transverse leaf springs front and back and was dangerous to drive especially on cabered profile roads as it had a tendancy to dive into the kerb. I saw an advert in the classifieds section of “Autocar” for a Panhard rod (16/10d). This came as a short rod silent block ends and replacement (longer) shackle pins. It fitted on one side of the leaf spring anchored to a point on the chassis. It therefore allowed the wheel (front steering) to move in an arc up and down but stopped any lateral movement of the steering. To fit it you jacked up the end of the spring to take the weight of the car off the spring so that when the Ford shackle pin was knocked out, the spring didn’t fall on the ground. The supplied longer pin was then inserted and the rod attached. A nut was then tightened to secure the joint. The same procedure at the outer fixed end.

I still remember the effect this simple mod had. You could drive on a cambered road “hands off” without any ill effects. I then bought a set of “Ridemaster” springs for the rear transverse suspension. This was mainly to stabilise the car if you were towing and consisted of two stout coil springs in line with a tensioning thread in the middle.

Unfortunately I was unable to fit it myself as the clip end was a force fit around the end of the leaf spring. Fortunately one of my minor customers ran a bit of a garage on the side. He put my car on a ramp and using a lump hammer drove the clip over the end of the spring. I then tightened the tension until it was just taut with the car at rest. On cornering it added massively to the strength of the leaf spring. I used to chuckle at the rear view mirror at hapless motorists following me through fast bends.

Back to the Ford 8 cylinder head. I didn’t fit this until we moved to Manchester. As purchased the compression ratio was a laughable 6.16 to one. With the 8 head the CR was a super modern (for 1956) 8:1!!

Obviously it was going to ‘pink’ so I bought a spare choke control which the cabling enabled the control to stay put. The engine end of the cable was attached to the side of the distributor which was mounted on a lug on the side of the cylinder head. I fitted a washer here which allowed free rotation of the distributor.

Any sign of pinking and I pulled the knob on the dashboard out slightly until the pinking stopped. This was during petrol rationing and if I stopped out in the sticks for petrol and bought super shell 100 octane I was often offered more than I had coupons for.

Windscreen washing was achieved by fitting a bracket on the dashboard to hold a narrow polythene bottle which you squeezed and hey presto a small jet hit the windscreen!

The wipers worked by the vacuum in the inlet manifold. At a steady 30mph on a flat road they worked perfectly, they slowed and stopped if you accelerated, going up a long hill you had to keep lifting your foot to get a few wipes. Solution a vacuum reservoir which gave you a few more vital seconds.

You have to remember that in the 50s there were specialised shops for car bits and pieces for maintenance or modification. Cars were simpler then. My piece de resistance however was my own invention. Castrol oil was sold in round tins with a conical top and screw top about 1 ½ ins in diameter. I sawed off the top (all the conical bit and a bit of side) I then found some electrical protection tubing of push fit diameter to the screw and which stayed in the shape you curled it.

Next I discovered that brazing wire could be tapped, 16BA. Top 4” of radiator blanked off

except for about 4” at one side with tin plate. Same at engine side of the radiator but at the other side so I was forcing hot air in at the left and out at the right. A radiator has horizontal plates so the ram air (only when car in motion) passed across the full width of the rad and not up or down. The can top was soldered at the opening of the back piece. The length of electric bendy pipe was pushed on and fed through a hole I cut in the lower bulkhead to come into the cab just above the passengers feet. The plates were held in place by VERY carefully feeding the tapped brazing wire through holes in the plates and through the radiator being secured by tiny nuts ! There was no temperature control, the passenger just pushed the tube to one side if things got too hot!

On a trip to Wragby, the racket from the engine suddenly stopped. At 40mph I tentatively switched off the ignition which caused immediate deceleration, so I switched on again and stopped to look. I had shed a fan belt. I fitted another and pressed on. It then dawned on me that the fan was the source of the noise, so I took it off and never replaced it till I sold the car. As long as the water pump was going the water temp never got too hot even when commuting via Oxford St in Manchester.

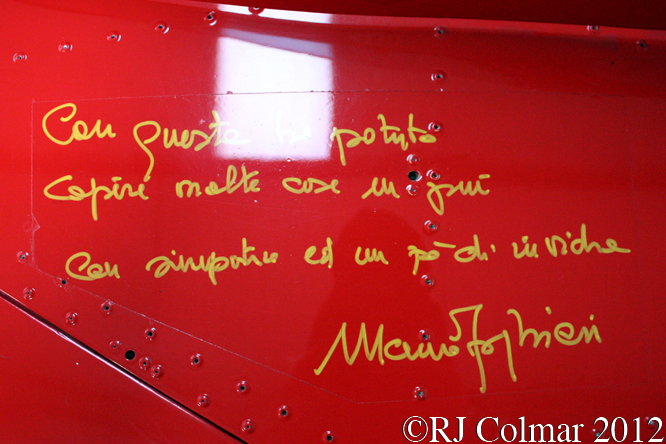

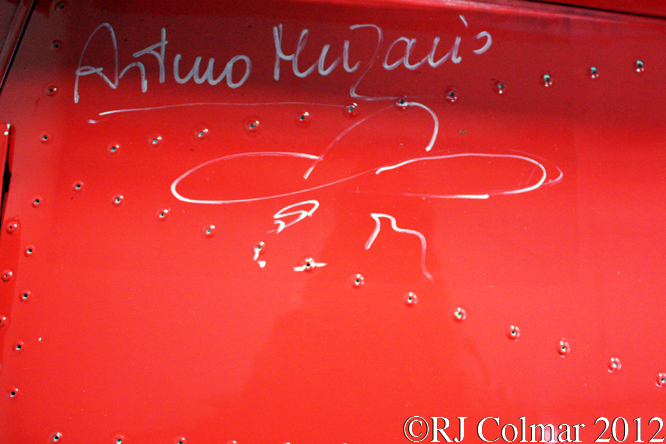

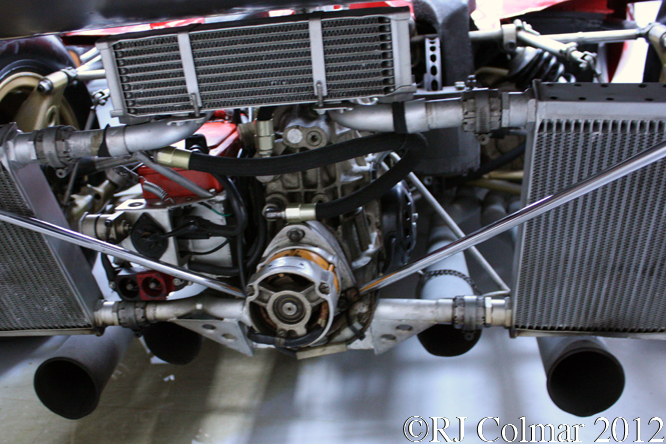

The tiny headlights (6 volt!!) were useless so I fitted twin “Notek” spotlights, in the process finding out that the painted bumpers were made from spring steel and were undrillable. Fitted a Mangoletsi inlet manifold swirler. A Servais straight through silencer and a short circuit plug which put the circuit breaker to earth as an immobiliser.

Nobody ever kept up with me 0-30 but tyre wear was a problem till I fitted Michelin X to the 450-17” wheels.

My thanks to everyone including the Mike and Neil Allen for your continuing support, looking forward to the next edition of Gettin’ A l’il Psychoontyres, don’t forget to come back now !